Nathupur, Sonipat, Haryana

- GST NO. : 06AABCS4256N1Z2

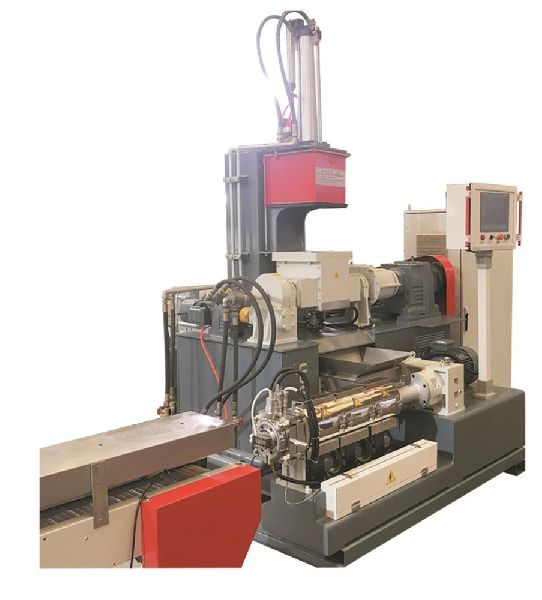

Lab Dispersion Kneader: Enhancing Efficiency And Quality In Material Processing

Posted by Admin on June, 29, 2023

A specialized device used in research institutions to mix, knead, and distribute materials is called a lab dispersion kneader. We will learn the characteristics, advantages, and uses of lab dispersion kneaders by Lab Dispersion Kneader Manufacturers.

Getting to Know Lab Dispersion Kneaders

A high-performance mixing device made for small-scale material processing is a lab dispersion kneader. To obtain homogeneous mixes and the necessary material qualities, it combines numerous materials.

Effective Kneading and Mixing

To effectively blend and disperse materials, lab dispersion kneaders combine mixing, kneading, and shear forces. The machine's architecture guarantees complete and consistent mixing, which yields materials of constant quality.

Processing of Materials with Flexibility

Rubber, polymers, chemicals, composites, and other materials may all be processed using lab dispersion kneaders by Lab Dispersion Kneader Manufacturers. They are perfect for small-scale production, formulation testing, and research & development.

Adjustable and Precise Control of the Parameters

These kneaders provide fine control over variables such as mixing time, temperature, and speed. As a result, scientists and engineers can optimize material compositions and provide the required material properties.

More Homogeneous Material Properties

Even when working with difficult or very viscous materials, lab dispersion kneaders excel at obtaining material uniformity. Agglomerates are broken down and uniform dispersion is ensured by the processing's shear forces and kneading motion.

Transfer of Heat Effectively

Lab dispersion kneaders have effective heat transmission components, including temperature-controlled or jacketed mixing chambers. As a result, the material's processing temperature may be precisely controlled, improving thermal stability and performance.

Degassing of Enhanced Materials

Degassing capabilities are often found in lab dispersion kneaders. This enables the removal of trapped air or volatile substances from the substance. As a result, high-quality materials with enhanced mechanical and chemical characteristics are produced.

Production On A Small Scale And Formulation Testing

Lab dispersion kneaders are useful equipment for formulation research and small-scale manufacturing. Before scalability for a bigger production, researchers may precisely reproduce processing conditions and assess material performance.

Development Of New Products And Quality Control

Lab dispersion kneaders' precise control and reliable performance help to ensure the quality of material processing. They are necessary for creating brand-new goods, enhancing formulas already in use, and realizing desired material features.

Space-Saving and Compact Design

Lab dispersion kneaders have a small footprint and are made to fit in lab facilities. This guarantees effective use of the available space and offers the processing power required for research and development.

Simple to Use and Maintain

These kneaders are made to be simple to use and maintain. A fluid workflow in laboratory settings is facilitated by accessible controls, easy cleaning, and little downtime for maintenance.

Cost-Saving Approach

Lab dispersion kneaders offer an affordable option for processing tiny amounts of material. They do away with the requirement for material development to be outsourced, giving researchers full command over the formulation procedure.

Conclusion

Lab dispersion kneaders are essential equipment for labs and research centers. This is because they make it possible to efficiently combine, knead, and disperse materials. These machines improve material processing, formulation testing, and small-scale manufacturing because of their adaptability, fine control, and reliable performance.

Improved material homogeneity, effective heat transmission, better degassing, and simplicity of use are all advantages of lab dispersion kneaders. Researchers and engineers may create dependable and high-quality material compositions with the help of a lab dispersion kneader. This fosters innovation and improves scientific understanding across a range of sectors.

Search

Category

- Rubber Dispersion Kneader Machine (5)

- Dispersion Kneader (4)

- Industrial Kneader Machine (3)

- Mixing Mill Fully Unit Drive (2)

- Hot Feed Rubber Extruder (2)

- Rubber Mixing Machinery (2)

- Hot Feed Rubber Extruder Manufacturer (2)

- Unidrive Rubber Mixing Mill (2)

- Lab Dispersion Kneader (1)

- Bucket Conveyor (1)

- View More

Recent Posts

- Trusted Manufacturer & Exporter of High-Quality Rubber Mixing Mills

- Hot Feed Rubber Extruder – The Workhorse of Rubber Processing

- Top Reasons to Choose an Automatic Rubber Mixing Mill Machine for Your Factory

- Key Factors to Consider Before Choosing a Dispersion Kneader Machine Supplier

- Understanding Industrial Kneader Machine Suppliers: A Comprehensive Guide

Leave a Comment