Nathupur, Sonipat, Haryana

- GST NO. : 06AABCS4256N1Z2

Crucial Features Of Mixing Mill Fully Unit Drive

Posted by Admin on March, 31, 2023

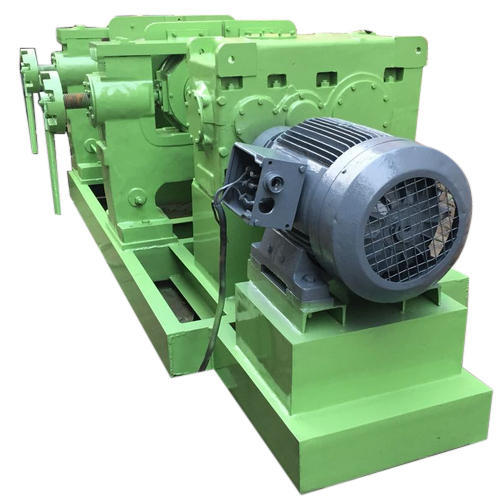

A mixing mill fully unit drive is a type of machine used in the rubber industry. It is used to mix and process raw materials into a homogenous compound that can then be processed into different rubber products.

All of the machine’s functions, including the mixing rolls, stock guides, and stock blender, are powered by a single electric motor. The Fully Unit Drive mixing mill features a completely integrated and automated drive system. Many benefits of this design include increased operator safety, improved energy efficiency, and less maintenance needs.

Mixing mill fully unit drive is a contemporary and sophisticated version of the conventional mixing mill. It has a number of characteristics that make it effective, secure, and practical to use. Mixing Mill Completely Unit Drive has several important characteristics, including:

Integrated Drive System

The energy efficiency is increased while maintenance requirements are decreased.

A single electric motor drives all of the mixing mill’s features, such as the mixing rolls, stock guides, and stock blender.

Control System for Automation

The automated control system that is part of the mixing mill fully unit drive. This enables precise management of the mixing procedure, delivering consistent results, and lowering the possibility of mistakes.

Innovative Safety Features

Advanced safety measures including emergency stop buttons, interlocks, and safety guards are included in the machine. This guards against mishaps and guarantee operator safety. These safety elements include, among others:

• Pull-tabs For Emergency Stops

Emergency stop buttons on the machine allow for an instantaneous shutdown in the event of an emergency.

• Interlocks

The machine is equipped with interlocks that stop it from operating if the safety guards are not securely fastened. The machine is equipped with safety guards that shield the operator from moving parts.

Uniform blending

A homogenous, impurity-free rubber compound is achieved. It uniformly mixes the raw components in the mixing mill with fully unit drive.

Blending Stock

The raw materials are more evenly dispersed throughout the concoction thanks to the stock blender feature.

Easy-to-use Interface

Operators may easily monitor and modify the mixing process using the Mixing Mill Fully Unit Drive's user-friendly interface.

Compact Style

The Mixing Mill Completely Unit Drive’s space-saving design makes it ideal for both large- and small-scale rubber processing plants. This is because it conserves space in the production area.

Less Impact On The Environment

The totally unit drive system uses less energy. It means there are fewer carbon emissions and fewer negative environmental effects.

The rubber compound is mixed and kneaded in the mixing mill by two horizontal, counter-rotating rolls. Making ensuring that the raw materials are distributed evenly throughout the combination is assisted by the stock guides and stock blender.

Conclusion

Mixing mills are a crucial component of the rubber sector and are used to manufacture a variety of rubber goods. These include tyres, hoses, belts, and seals. The Completely Unit Drive design a contemporary take on the conventional mixing mill, has grown in popularity recently. This is due to to its increased effectiveness and less environmental impact.

Search

Category

- Rubber Dispersion Kneader Machine (5)

- Dispersion Kneader (4)

- Industrial Kneader Machine (3)

- Unidrive Rubber Mixing Mill (2)

- Mixing Mill Fully Unit Drive (2)

- Hot Feed Rubber Extruder (2)

- Rubber Mixing Machinery (2)

- Hot Feed Rubber Extruder Manufacturer (2)

- Rubber Sheet Making Machine (1)

- Rubber Bale Cutting Machine (1)

- View More

Recent Posts

- Trusted Manufacturer & Exporter of High-Quality Rubber Mixing Mills

- Hot Feed Rubber Extruder – The Workhorse of Rubber Processing

- Top Reasons to Choose an Automatic Rubber Mixing Mill Machine for Your Factory

- Key Factors to Consider Before Choosing a Dispersion Kneader Machine Supplier

- Understanding Industrial Kneader Machine Suppliers: A Comprehensive Guide

Leave a Comment